What is Cargo Liquefaction?

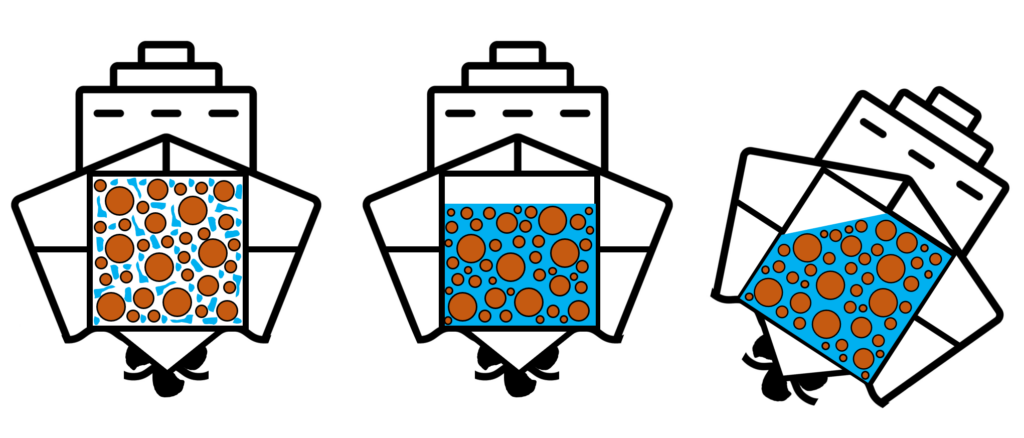

Cargo liquefaction takes place when a dry bulk cargo with high moisture content loses its strength and transforms from a solid dry state to an almost fluid state. As the cargo starts to behave like a liquid when the ship is moving, it can shift rapidly in the hold of a ship, making the ship unstable (Fig 1) and causing it to capsize resulting not only in the potential loss of a vessel but also the loss of life.

Cargo can be exposed to agitation through loading from a height, during a voyage because the vessel encounters rough seas, or merely as a result of vessel vibrations resulting in compaction of the cargo, which in turn, can lead to liquefaction. Commonly known cargoes that pose this type of hazard are iron ore fines and mineral concentrates.

Governing legislation

A ‘Group A’ cargo is one which may liquefy if shipped at a moisture content (MC) in excess of its transportable moisture limit (TML) and mitigation measures are required to reduce the risk of liquefaction. The International Maritime Solid Build Cargoes [ii] provides information and instructions that should be followed to help facilitate the safe stowage and transport of these Group A cargoes.

The IMSBC Code is mandatory and provides specific guidance on how cargo should be stored, loaded and transported. Key requirements include:

- The Shipper shall provide the Master with a signed certificate of the TML, and a signed certificate or declaration of the MC, each issued by an entity recognised by the competent authority of the port of loading.

- The certificate of TML shall contain, or be accompanied by, the result of the test for determining the TML.

- The Code requires that the time between testing for the MC and loading shall be no more than 7 days.

The testing date and raw data to evidence the tests should also be disclosed, as without this it is not possible to determine the accuracy of the results and whether the requirements of the IMSBC Code have been complied with.

The Can-Test

The Can-test is a supplementary ad-hoc test that can be conducted on board or at the dockside to help determine if a cargo might be unsafe or if the cargo might “flow”. The test is to put some cargo in a can, bang it on the ground or on the side of the can and then check to see if the contents start to flow. To assist the crew/surveyor in determining the above, it is prudent that the Can-test is conducted on samples regularly.

Masters should be familiar with the Can-test and whilst a simple process, the IMSBC Code provides instruction on how to conduct this correctly for accurate results.

How Can the Risk of Liquefaction be Mitigated?

The most effective way to reduce the risk posed by Group A cargoes is to follow the Code accordingly. Owners should also take the initiative to request additional information from Shippers to ensure that they are fully aware of the condition of the cargo when it is loaded on to the ship.

1. Sampling/Testing

According to the IMSBC Code, the test to determine the TML of the cargo should be conducted within 6 months prior to the date of loading and the test to determine the MC should be carried out no more than 7 days prior to the date of loading. To ensure that the TML and MC values are reliable it is crucial that representative samples are taken from the stockpiles where the cargo is being stored and that the sampling/tests are carried out by an accredited third-party laboratory.

The certificates issued by the laboratory should provide details of:

- When and how the samples were taken (including any internal sampling report);

- Details of when and how the TML test was undertaken;

- Details of when and how the MC was determined;

- Raw data supporting the results.

Weather logs for the anchorage/stockpile/mine and loading port should also be provided for the 7 days prior to loading and if precipitation or rain was noted during this period, then the cargo should be re-sampled and tested prior to loading. Owners should also request that Shippers have provisions to protect the cargo from rain during loading and ensure that the barges carrying the cargo have proper water-draining facilities.

2. Loading cargo

Owners should appoint a reputable and competent surveyor to oversee the loading process and an expert to supervise and provide technical support to the surveyor throughout loading.

Prior to loading, the Code requires that the bilge wells are clean, dry, and covered as appropriate, to prevent ingress of the cargo. The bilge system should be tested to ensure that it is working, and the crew should also sound the bilges during loading for evidence of water draining.

During loading, the surveyor should perform regular Can-tests of the cargo. The surveyor should describe in detail how the tests are being undertaken and take videos of the tests to ensure that they are being conducted according to the Code. The surveyor should also take high-resolution photographs of the sample before and after conducting the test to allow comparison of the results. If loading takes place through the night, the surveyor should also designate a crew member to assist as Can-tests need to be conducted periodically.

Warning sings are:

- A Can-test showing a pancake appearance with a glossy surface or free water.

- Following the Can-tests, the cargo clumps together instead of crumbling apart.

- The cargo can be moulded by hand like a modelling clay and retains a compressed shape.

The surveyor should look for signs of splattering during loading, and instances where the cargo sticks to the grab’s jaws (if loading uses a grab). Special attention should be given if the grabs are lowered to the bottom of the hold before the jaws are opened as this is a common practice when loading wet cargo. The surveyor should note down all instances of cargo wetting by rain and ensure that no loading takes place when it rains. The cargo on the barge or in the stockpile should be covered with tarpaulins and the crew should close the hatch covers during rain and beforehand if sufficient weather data is available to indicate the likely onset of rain.

If the cargo has been exposed to rain, it is prudent that further laboratory tests rather than Can-tests are conducted to ensure that the MC is still below the TML. Until a new MC (from an accredited laboratory) has been provided by Shippers, the Master should ensure that no loading operations take place. Owners should also ensure that Shippers provide a new MC certificate if the testing date on the certificate initially provided has exceeded 7 days.

3. The Voyage

Following loading, the cargo should be trimmed to reduce the likelihood of the cargo shifting. The Code also requires that the appearance of the surface of the cargo is checked regularly during the voyage. As such, it is highly recommended that the crew conducts daily voyage inspections of the cargo (weather permitting), takes photos of the cargo, and keep records of the cargo condition. The crew should also take daily cargo hold bilge records and ensure that water is drained from the hold if the bilge wells become full. To protect Owners from any cargo shortage claims which may be presented by Receivers, it is recommended that a record is made of the amount of water pumped from the bilges during the voyage.

If the cargo appears to liquefy during the voyage, then the Master should inform Owners immediately and then either the Master or Owner should take the following steps:

- Contact the nearest coastal state authority;

- Contact their P&I Club;

- Consider calling at the nearest port or place of refuge.

In the meantime, the Master should also consider reducing the ship’s motion/vibration.

Cargo liquefaction continues to be a major concern for the shipping industry. However, the risk can be minimised greatly if attention is paid to the guidance of the Code and appropriate action is taken prior to and during the loading of Grade A cargoes.

How Hawkins Can Help

At Hawkins, we can provide advice on suitable sampling methods and appropriate laboratory conduct, both of which will assist in determining whether the cargo is safe for loading. We can attend onboard vessels to witness the sampling and at laboratories to witness the testing of the samples. If attendance is not possible (for example due to Covid-19 and its associated travel restrictions), we can also liaise with local surveyors and help supervise the whole loading process remotely to ensure that Can-tests are performed regularly and accurately.

About the Author

Jessica Ng is based in Hawkins’ Hong Kong office and specialises in cargo liquefaction cases, agricultural cargo claims and fire and explosion investigation. She regularly assists P&I Clubs in supervising the loading process of Group A cargoes and has been involved in cases involving the liquefaction of cargoes such as nickel ore and iron ore.

[i] https://www.amsa.gov.au/vesselsoperators/cargoes-and-dangerous-goods/dynamic-separation-cargoes

[ii] https://www.mlit.go.jp/common/001249851.pdf