Paint & Coatings

Coatings of objects can range from electroplating of metals to physical paint being applied. The most important reason to coat a material is invariably to protect it from degradation; corrosion in the case of metals and rot in the case of natural materials. Coatings can and do fail to provide the necessary protection.

Sometimes failure of coatings is related to poor installation techniques or curing environments, but sometimes it is related to manufacturing processes and the raw materials used. In-depth analyses of the issues including examination of the coating on a nano scale can provide the answers necessary to evaluate the problem.

WHY APPOINT A FORENSIC INVESTIGATOR?

Our expert materials scientists and engineers have years of technical and practical experience of investigating materials failures.

We have the technical knowledge and experience to decipher the circumstances leading to a paint or coating failure, and to advise on the next best steps.

- We have an in-depth knowledge of the regulations and guidance that should be followed by technicians and engineers who prepare the various surfaces, apply the coatings, and oversee curing.

- We review working practices and installations to identify areas at high risk of a fault.

- We offer guidance and/or help you define and develop good working procedures and practices to reduce the risk of paint and coating failures occurring.

- We provide you with the answers you need to determine why an incident occurred and so assist in repudiation/cover decisions and fraud identification.

- Our experts are knowledgeable in a wide range of areas pertaining to coatings and can investigate all aspects of a failure, so you only need to instruct one expert, rather than several.

- We have laboratories and equipment designed specifically to investigate materials failures, with powerful, state-of-the-art stereomicroscopes.

- We will help you to determine if an incident could have been avoided.

- We support subrogation/recovery efforts.

- We help you to make decisions regarding where legal responsibilities/liabilities lie.

- We help you to defend wrongful claims.

- We produce reports suitable for Court and litigation.

- We provide consultancy advice to prevent similar events happening again in the future.

- If removing a risk entirely is unavoidable, we advise on steps to take to mitigate the risk and reduce the potential damage resulting from an incident.

- We advise on servicing, maintenance and repair regimes.

Examples of Typical cases

- Examination of paint coatings to cars, buildings, trains and metallic structures

- Investigation into the suitability of intumescent paints

- Osmotic blistering of paints on surfaces

- Failure of protective polymer film on glass windows

- Enamel coating failures in hot water cylinders

Our services are flexible and can be tailored to your needs, depending on the scale and urgency of the investigation. Our services range from a free consultation through to a full investigation including a court-compliant report for the support of legal action.

If you would like to discuss how we can assist you please fill out our enquiry form or call us for a free consultation.

HOW DOES HAWKINS INVESTIGATE PAINT & COATING FAILURES?

1

Consultation

We like to speak to our clients before conducting any work so that we can understand and plan how we can add the most value to any case. We will discuss your requirements, determine what information is already available and who the best people are to contact to fully understand the background of the case. We are also happy to provide you with a cost estimate and time scale to conduct a forensic investigation.

2

Inspection

If required and with your agreement, we will arrange to visit the scene to inspect the damage. Wherever possible, we will retain faulty parts for examination in our laboratory, where we use a range of equipment, tools, and tests to determine the cause of the failure. This could include microscope examinations, recreating an installation in a controlled environment, or testing exemplar components or materials.

3

Conclusion

Once our examination is complete, we will discuss our findings with you and prepare a report containing a detailed account of our investigation, conclusions, and where appropriate, further work or advice.

Case Study

Peeling planks…

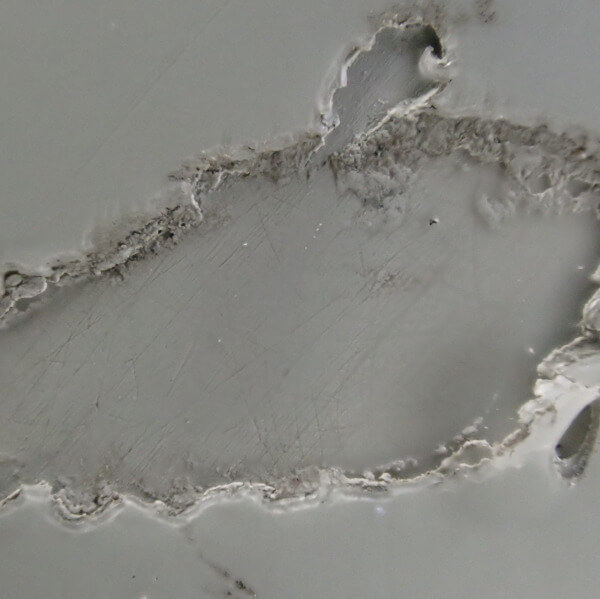

Paint applied to a new build development of wooden houses was exhibiting poor adhesion and the paint was peeling.

A variety of studies were carried out to the houses, including thermal imaging, moisture mapping and adhesion tests.

The wooden planks had been poorly prepared and were not painted on their cut, grain ends. Wood is hygroscopic (particularly through the grain) and exposure to the moisture in the environment had caused the planks to expand and contract, affecting the bond between the wood and the paint, causing it to flake off.

This required remedial works to the entire development of over 100 houses.

SPEAK TO ONE OF OUR EXPERTS

Testimonial

“Thank you for your superb effort in this case.”

Rhys Phillips

“Many thanks for turning out today at such short notice and providing the benefit of your expertise and knowledge. It was evident the Client was extremely relieved that this matter was being investigated expeditiously.”

Chaz Winterton

“I just wanted to say thank you for all your help and the information you found was of real insight. Thank you again for all your help.”

Stewart Hargreaves

“I just wanted to say thank you for all of your hard work preparing the Hawkins report. Please pass on my thanks to the rest of the team. We really appreciate the hours you have all put in and I know the client is pleased with your work.”

Philippa Jones

“I have recently needed structural engineering opinion on one matter and geotechnical engineering opinion on another. I experienced the usual difficulties with traditional providers of those services – excessive cost, inability to get on site quickly etc etc. When turning to Hawkins the contrast was clear – economical pricing, fantastic turnaround times, and really helpful reports that focussed on my needs without me needing to spend ages spelling it all out.”

Hawkins client

Related areas of expertise

Metallurgy

Losses involving metallurgical failures occur in a wide range of industrial and domestic environments and can lead to high value claims or even loss of life.

Chemical & Process Engineering

Chemical Engineering and Process Engineering are essentially interchangeable terms, whether it is engineering chemistry to make a desired product on the industrial scale for example a pharmaceutical drug or a beer or simply process materials for some beneficial purpose for example in water treatment or renewable power generation.

Chemistry

Chemistry is an integral part of modern life, both in the commercial and domestic world.

Composites

A composite material is any multicomponent material that contains two or more distinct constituents or phases, i.e. it is made from a combination of two or more different types of constituent material. Perhaps the most familiar examples in modern engineering are glass or carbon fibre reinforced plastic (GFRP or CFRP).

Glass & Glazing Systems

Architectural glazing has become increasingly prominent in commercial, retail and residential developments over the last 30 years. Hawkins has extensive experience on cases in this area and are well equipped to rapidly investigate a full range of possible issues.