Composites[1], attractive because of their low weight and high strength, are common throughout the construction industry and are used for both structural and aesthetic purposes. Laminates are a type of composite, manufactured from multiple layers of materials that are stacked on top of each other and joined together using a combination of pressure, heat and adhesives. Laminates are commonly used for decorative purposes, such as floors, as well as door and furniture surfaces.

This article discusses some of the common problems that cause laminates and their underlying substrates to become ‘unbalanced’. This can not only be unsightly but can also cause the product to no longer fulfil its expected safety requirements.

Laminate Manufacture

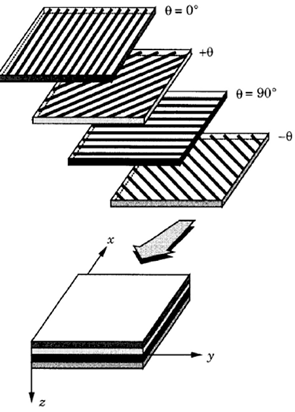

Typical composites are made up of fibres, which provide mechanical strength, and a matrix, which transfers the load between the fibres. The resulting material has features of both the fibre and the matrix. Laminates are classified as a type of composite comprising sheets or panels (lamina) that have a preferred high-strength direction. These layers are stacked and glued together such that the orientation of the high-strength direction varies with each layer; these stacks are then adhered to a substrate, typically wood.

A schematic drawing of how these layers can be stacked. [2]

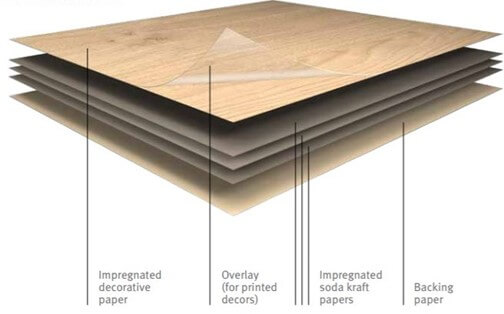

Decorative laminates are typically constructed from kraft papers impregnated with resin that adhere to the back of decorative paper. The fibres in the paper give the mechanical strength in tension and the material used to impregnate the paper is the matrix, providing the compressive strength when bent. It is important to note that the kraft papers used have a fibre orientation and can be laid to maximise the mechanical strength in a particular direction.

Each laminate has multiple layers of this paper which are then compressed and adhered to each other using either a high-pressure system or a continuous high-pressure system.

High-pressure laminates (HPL) consist of multiple layers of kraft paper which have been saturated in a phenolic resin. A decorative layer of paper saturated with a melamine resin is then applied on top. These are then compressed in a static press at pressures ≥ 50 bar and temperatures ≥ 120˚C to form the finished laminate. Laminates manufactured in this way are typically used for panels that are likely to be subjected to a high wear, such as work tops. BS EN 438, the standard for high-pressure decorative laminates, states that the minimum permitted thickness of the laminate is 0.8 mm ± 0.1 mm.

The process for manufacturing continuous high-pressure laminates (C-HPL) differs in that, whilst the pressures and temperatures used to make these laminates are similar to those used in HPL, the laminates are passed through a continuous roller, allowing for faster and more efficient manufacturing.

Unbalanced Laminates

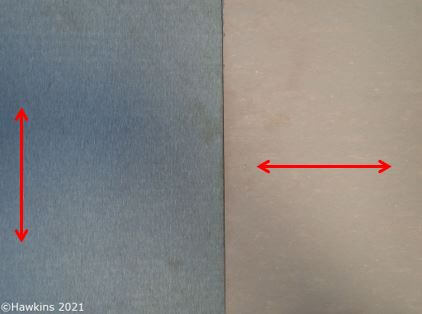

As described above, the kraft paper used to manufacture laminates has a fibre orientation that will affect the mechanical properties of the laminate, as will the thickness of the laminate and how the laminates have been manufactured. One of the most common problems encountered when using laminates[3] is warping, caused by unbalanced panel construction.

There are several factors that can cause a panel to become unbalanced. These include (but are not limited to):

- The specification of the laminates used on each face – laminate manufacturers allow the customer to choose what laminates they want installed on their product. For example, a customer might want a door with one type of laminate installed on the inside face, and a different laminate on the outside. When materials with different properties are rigidly glued together, changes in moisture content across the panel can occur, which causes the materials to try and change shape (expand or contract). When this happens, stresses can accumulate. The panel will warp if the stresses on one side of the panel are significantly larger or smaller than on the other side of the panel i.e., the panel is unbalanced.

- The orientation of the laminates used – where different fibre orientations are used.

- Pre-conditioning of the laminate – this is carried out before bonding of the lamina and substrate and involves storing all materials used at a controlled temperature and humidity. This minimises the differential movement caused by changes in temperature and humidity.

- Conditioning of the laminate – the fully constructed laminates are typically stored in the environment in which they are to be installed in for several days to allow them to acclimatise to the environment.

Another key factor to consider is the end environment in which the laminates are to be installed; large variations in temperature or relative humidity can cause the product to warp or distort after it has been installed.

Warping, whether caused by unbalanced construction, inadequately conditioned materials or the end environment is of particular importance when the product is required to conform to a specific standard or is safety critical, for example, the use of laminates in the manufacturing of fire doors, which are required to have maximum gaps between the door and the frame to allow for the proper operation of the smoke seals.

About the Author

Christabel is a Materials Engineer with extensive experience in the failures of polymers, metals, glass, composites, escapes of water and oil, mechanical system failures and personal injury claims.

She has written several CPR-compliant court reports and regularly presents at industry awareness days. She is well-versed in the testing and characterisation of conceptual and current materials and has experience in failure analysis of electrical components.

Hawkins has the technical knowledge and experience to tell you why a materials failure occurred, not just what caused it. Our services range from a free consultation through to a full investigation including a court-compliant report for the support of legal action. If you would like to discuss how we can assist you, please fill out our enquiry form or call us for a free consultation.

References

[1] Comprising of two or more materials with different physical and/or chemical properties.

[2] Source: https://www.researchgate.net/figure/A-laminate-made-up-of-lamina-with-different-fiber-orientations_fig2_308721666.

[3] Bent or twisted out of shape.