In the maritime industry, tanker vessels are chartered to carry various products and as part of this remit, the shippers are required to conduct sampling to ensure that the cargo being loaded is of a suitable quality and meets a particular specification or contractual requirement.

In this article, we provide brief explanations for some of the technical aspects of the sampling of hydrocarbon products (such as petroleum, fuel, and oil) in tanks, the different types of samples to obtain a representative composite sample of a tank for analysis and the trend of including the bottom sample.

Energy Institute (EI) and American Petroleum Institute (API) committees, under the cover of various publications, consider sampling methodology as evidence of best industry practices in manual sampling of hydrocarbon products in both ship and shore tanks. Guidance on sampling can be found in the following:

- API MPMS Chapter 8.1 Standard Practice for manual sampling of petroleum and petroleum products 6th Edition 2022.

- ASTM D4057 – 22 Standard Practice for manual sampling of petroleum and petroleum products.

- HM93 1st Edition “Guide to Manual Sampling of Hydrocarbon Products”.

As set out in API MPMS Chapter 8.1, the intention behind the sampling is to obtain a small sample that is representative, either of a particular point in the tank, or of the cargo in the tank as a whole.

- Manual Sampling Concepts and Objective

- §8.1 Objective of Manual Sampling -The objective of manual sampling varies. In some instances, the intention is to obtain a small portion of product that is representative of the tank or container contents. In other instances, samples are specifically intended to represent product only at that one particular point in the tank, such as a top, dead bottom, or suction level sample. When a tank is determined to be homogenous, a series of spot samples may be combined to create a composite sample.

API MPMS Chapter 8.1 also defines a representative sample as:

- § 3.3.19 representative sample – a portion extracted from the total volume that contains the constituents in the same proportions that are present in that total volume.

To put this into context a single litre sample may be required to be representative of a tank that holds many thousands of litres of product.

The definitions of the various level samples in API MPMS Chapter 8.1 are as set out below:

- §3.3.8 dead bottom sample – a sample obtained from the lowest accessible point in a tank. This is typically directly from the floor (or datum plate) of the shore tank or the bottom of the vessel compartment.

- §3.3.3 bottom sample – a spot sample collected from the material at the bottom of the tank, container, or line at its lowest point. In practice, the term bottom sample has a variety of meanings. As a result, it is recommended that the exact sampling location (for example 15 cm (6 in.) from the bottom) should be specified when using this term.

- §3.3.16 lower sample- a spot sample of liquid from the middle of the lower one-third of the tank’s content (a distance of five-sixths of the depth liquid below the liquid’s surface).

- §3.3.17 middle sample – a spot sample taken from the middle of a tank’s contents (a distance of one half of the depth of liquid below the liquid’s surface).

- §3.3309 upper sample – a spot sample taken from the middle of the upper one third of the tank’s contents (a distance of one-sixth of the depth of the liquid below the liquid’s surface).

- §3.3.28 top sample – a spot sample obtained 15 cm (6 in.) below the top surface of the liquid.

- §3.3.24 surface sample (skim sample) – a spot sample skimmed from the surface of a liquid in a tank.

- §3.3.20 running sample – a sample obtained by lowering an open sampling device to the bottom of the outlet suction level, but always above free water, and returning it to the top of the product at a uniform rate such that the sampling device is between 70 and 85 % full when withdrawn from the product.

API MPMS Chapter 8.1 further states inter alia:

- §3.3.6 composite sample – a sample prepared by combining a number of samples and treated as a single sample.

- §3.3.25 tank composite sample – a blend created from a single tank, as an example combining the upper, middle, and lower samples. For tank of uniform cross section, the blend consists of equal parts of the three samples. A combination of other samples may also be used, such as running, all-levels or additional spot samples.

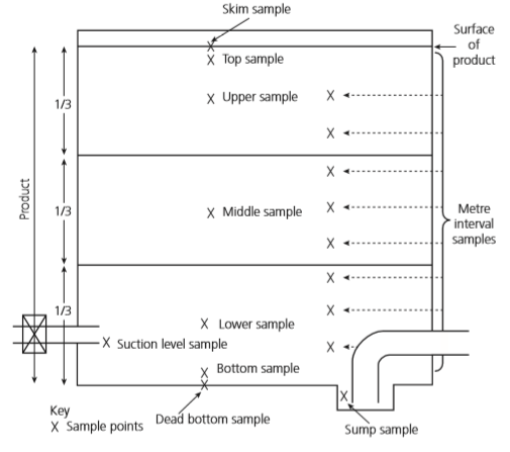

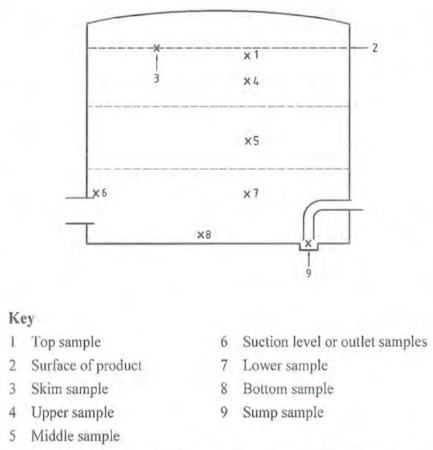

Some samples, such as Skim, Top, Bottom and Dead Bottom samples are representative of specific levels within a tank and so are not representative of the tank’s contents as a whole. They are only representative of the material at the position/level from which they are taken. Such “spot” sample types are shown in Figure 1.

For marine shipments Upper, Middle and Lower (U/M/L) samples in equal parts from each tank are generally adequate for creating a representative volumetric composite sample of the individual tank.

However, as set out in the API Standards, if the initial U/M/L samples show the cargo in the tank is non-homogeneous, it is recommended that additional spot samples at equidistant multiple levels should be taken.

Furthermore, as set out in HM93 §3.3, U/M/L samples “…should not be confused with Top and Bottom samples. Top and bottom samples cannot be relied upon to be representative of the bulk quality” and should not be used in the creation of a representative sample. They are used to determine the stratification and analysed in isolation with any technical interpretation thereafter.

API MPMS Chapter 8.1 raises the issue regarding water contents and non-homogeneity:

- §9.2.8.1 Water in Petroleum – The concentration of dispersed water in the oil is generally higher near the bottom of a tank or pipeline. A running or all-level sample, or a composite sample of the upper, middle, and lower samples, may not be representative of the concentration of the dispersed water present. The interface between oil and free water may be difficult to locate.

- §9.2.9 Depending on the extent of stratification, it can be very difficult to obtain a representative manual sample. Spot samples, such as upper, middle and lower (UML), or top, middle and bottom (TMB) are recommended to establish the extent of stratification. Running or all-levels samples will contain all product layers in the vertical column from the sample point, although the rate of fill will be variable based on the depth of the product. Even with care, it may not be possible to exactly reproduce a manual sample from a nonhomogeneous or stratified tank.

- §9.2.9 Spot samples may be taken to assess the level of stratification of a particular property within a shore tank or marine vessel compartment.

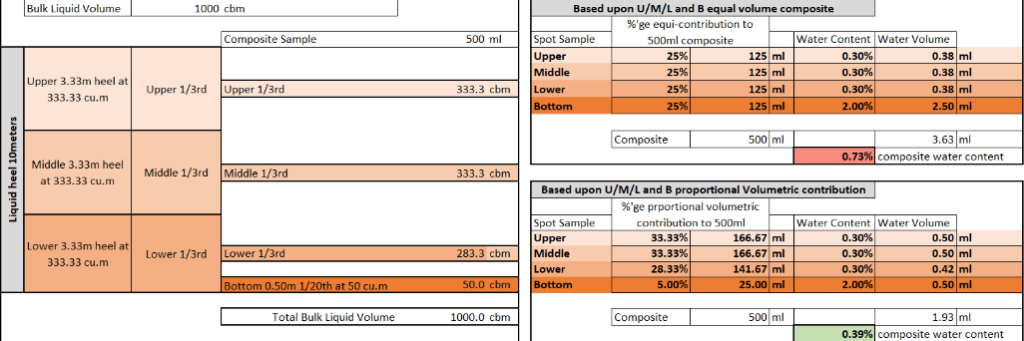

Sampling to create a representative sample of the bulk of the oil requires care and diligence. For example, a Bottom (B) (15 cm from the bottom) or Dead (absolute) Bottom (DB) samples are taken where, if water is present, there is likely to be a predominantly higher water content than compared to the bulk of the cargo above. If a Bottom or Dead Bottom sample is included in the composite with the Upper (U) (1/6th level from the surface), Middle (M) (3/6th from the surface or from the tank bottom) and the Lower (L) (1/6th from the tank bottom), then there is a disproportionate volume of lower sample volumes (50%) in the composite sample to be analysed (Table 1). Such a ‘composite’ may not be representative of the bulk cargo as a whole.

Inclusion of the Bottom sample 15 cm from the tank bottom has a disproportionate and potentially dramatic impact such as with ISO 8217 marine heavy fuel oil having a maximum water content specification of 0.5 vol%.

This can be shown by the calculation in Table 1. Consider a tank with a cross sectional area of 100 sqm and liquid heel of 10 metres, which contains a nominal 1,000 cbm. If a Bottom sample with a water content of 2 vol% is included, it contributes a disproportionate amount to the overall water content of a U/M/L/B volumetric composite sample. If the Upper, Middle and Lower samples have a homogenous water content of 0.3% then the derived water content of the apparent representative sample is 0.73 vol% and does not meet the 0.5 vol% water content specified by ISO 8127 for marine heavy fuel oil.

However, the Bottom sample actually forms only a 5% (or less depending upon the relative height of the liquid heel) proportional volume to the overall oil volume. So, if the Bottom sample’s contribution to the volumetric composite sample is commensurate to its proportional volume the resultant water content is only 0.39% meeting the ISO Marine Fuel Oil specification.

It is for this reason that Dead Bottom and Bottom samples are not included in the composite sample as they do not represent the whole volume of the cargo. This point is not only of significance in relation to bottom layers; it may apply to any stratified layer in a tank and indeed other potential parameters where the spot samples may induce a bias.

In addition, if, for example, there was a free water depth of say 2 to 3 cm on the bottom of the ship’s tank, a properly taken Dead Bottom sample could result in the whole sample being filled with water. A free water sounding of 5 cm may represent a maximum of 5 cbm of cargo, a minute percentage overall, but the sample’s inclusion in a composite could have a significant and disproportionate impact depending on how many samples are used to prepare the composite.

It is critical that decisions as to how to address quality issues are based upon analysis of a representative U/M/L sample or, if the cargo is stratified and non-homogeneous in the tank, then more, equidistant, level samples (perhaps at continuous 1 metre intervals) should be taken and analysed to allow assessment of each stratified layer. A properly taken running sample can also be considered but may have limitations as set out in API MPMS Chapter 8.1 “§9.5.3 …. running and all-levels samples may not necessarily be representative because the tank volume may not be proportional to the depth, and the rate of filling is proportional to the square root of the depth of immersion.”

In summary, Bottom and Dead Bottom Spot Samples should generally be excluded from representative composite samples.

In any event, the sampling strategy and any samples drawn are key in establishing an accurate profile of the product and extent of possible contamination, and an appropriate mitigation strategy in bulk liquid claims. They are also key to establishing the potential cause and source of contamination and recovery, notwithstanding exercising due diligence in careful storage, handling and carriage of the petroleum product.

How Can Hawkins Help?

Our Chemists and Marine Consultants can:

– Provide advice on the most appropriate sampling methodology for ship and shore tanks with due consideration of the nature of the products and issues of concern;

– Provide analytical and technical investigations to understand whether the product meets the specification;

– Identify the parameters and issues of concern;

– Assist in potential mitigation strategies;

investigate causation;

– Assess whether due diligence was exercised in the storage, handling and carriage of petroleum products;

– Consider whether ship and shore operations accord with good practice.

Captain Stewart Horan is a Master Mariner and a Principal Associate in Hawkins. Stewart has given evidence in the High Court and at Arbitration in United Kingdom, Oslo and Singapore on the carriage and handling of cargo, navigation, groundings, tanker operations, ship vetting, ship management and general shipboard operations including ship-to-ship (STS) transfers.