Hawkins was instructed to investigate the cause of a fire in an electric road sweeper which occurred at a council depot approximately ten minutes after a service engineer had repaired the sweeper.

Before an examination of the sweeper was carried out, the circumstances of the incident were discussed, both with the service engineer and the council employees who were present at the time of the fire. All available documentation, including a tracker log and service records, was also reviewed.

INVESTIGATING THE CAUSE OF THE FIRE – BACKGROUND INFORMATION

The service engineer had attended the depot to repair the sweeper following reports that it would not charge. The engineer traced the fault to a component in the battery pack. He replaced the component and when he reconnected the charger, the fault was resolved. He test drove the vehicle for ten minutes before leaving. The service engineer left the vehicle off charge and handed the keys into the main office at the depot. The timings on the tracker log were consistent with the engineer’s account.

Approximately ten minutes after the engineer left, a council employee found a well-developed fire burning inside the cab of the sweeper. The windscreen had failed and flames were ‘shooting out’ from the front of the cab at approximately steering wheel height. The council employee reported that both cab doors were closed and locked at that time.

INVESTIGATING THE CAUSE OF THE FIRE – EXAMINATION OF THE ROAD SWEEPER

The sweeper had sustained severe damage to its cab and all combustible components in the cab had burned. However, the batteries and hopper were undamaged by fire. There was no evidence of damage in the area where the service engineer had been working.

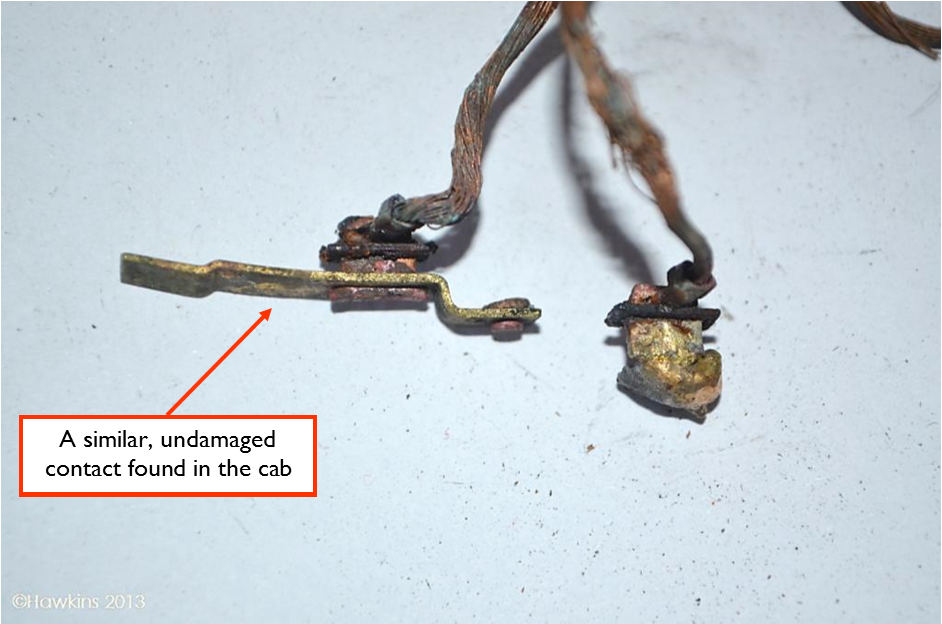

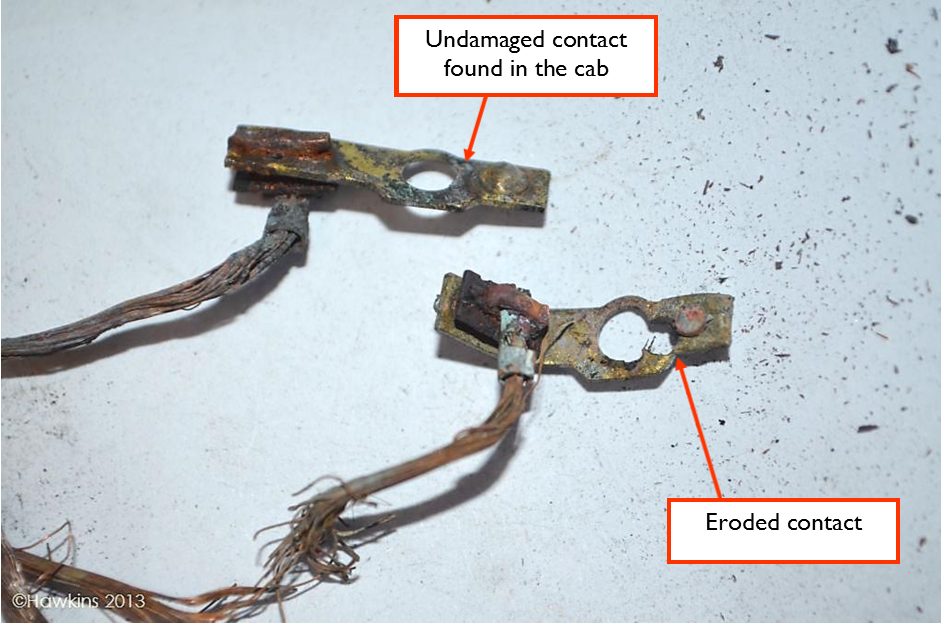

A detailed examination of the cab was carried out, with particular focus on the area around the steering wheel as the fire was first observed in that area. Despite the significant damage throughout the cab, our investigator found resistive heating damage at two switch contacts inside the cab.

When electrical current flows through a poor contact or connection (one with high resistance) it can generate heat. In extreme cases, sufficient heat can be generated to cause localised melting damage at the contact or connection and the ignition of any adjacent combustible materials.

INVESTIGATING THE CAUSE OF THE FIRE – EXAMINATION OF AN EXEMPLAR ROAD SWEEPER

Owing to the extent of damage to the sweeper, it was not possible to determine what the damaged switch contacts had been part of. However, an exemplar sweeper, which had been delivered to the council at the same time as the incident sweeper, was also available for inspection. Using the exemplar sweeper, the damaged switch contacts were identified as being from the multi-functional lever on the steering column.

The lever operated the horn, dipped headlights, main beam headlights (including flashing function), indicators, windscreen washer and wipers. Although most of the functions would not operate with the start switch in the ‘off’ position, it was still possible to flash the headlights. Therefore, it was apparent that the lever had a permanent live feed and that it would still be energised after the service engineer had switched off the sweeper.

A detailed examination of the multi-functional lever from the exemplar sweeper also revealed evidence of overheating; there was some discolouration and charring at a connector block.

The multi-functional lever was supplied to the manufacturer of the road sweeper as a pre-assembled component from one of their suppliers. However, they had recently changed their supplier of the component to one which provided the multi-functional lever for a fraction of the previous cost.

This was a case where the timing of the repair work and the fire suggested that the two were linked while in fact it was just an unlucky coincidence.

CONCLUSIONS AND RECOMMENDATIONS

Based on the resistive heating damage found at the switch contacts of the machine, it was concluded that the fire was the result of an incendive electrical fault at the multi-functional lever. This conclusion was reinforced by the evidence of overheating at the multi-functional lever on the exemplar machine.

It was recommended that the multi-functional levers of all in-service sweepers of the same type, which were provided by the new supplier, were inspected for evidence of overheating. The manufacturer of the road sweeper took a pro-active approach; they immediately carried out a recall of all in-service components and reverted to their previous supplier. This potentially saved them significant costs from further liability claims because, based on the damage to the exemplar machine, it is likely that there would have been further incidents.

ABOUT THE AUTHOR

Mr Darren Cook is a Senior Associate, Chartered Mechanical Engineer and an Associate Member of the Institution of Fire Engineers based in our Glasgow Office. Originally from a defence and marine engineering background, Darren has investigated a large number of vehicle, plant and machinery fires since joining Hawkins in 2011. Cases investigated include supercars, buses, tractors, grain dryers, loading shovels, excavators, bulldozers, screeners, crushers, road rollers and road sweepers.