I started my career working at LGC Forensics, now known as Eurofins, specialising in the examination and reporting of trace evidence, i.e. fibres, paint, glass, and foam. I loved investigating crime scenes to establish a forensic link between people and incidents.

I was known as the “Foam Queen” due to my interest in polyurethane foam evidence found in car seats, which could transfer onto the trousers of car thieves. I discovered that foams have reasonable evidential value, because of their distinctive pigments, dyes and differing rates of degradation. There are truly very few people who have the emotional and physical stamina to stare down a microscope for 8 hours a day, searching for foam on clothing and tapings taken from car seats. They were fun and challenging times and the foundation of my career in forensics.

Fast forward to 2012 and due to a family relocation, I found myself in Hong Kong.

I wondered if I could get a job in the local crime laboratory but my lack of the local language, barred me from such government-related work. Eventually, I found myself working as a forensic engineer, doing accident investigation on behalf of the insurance market.

My undergraduate degree and PhD were both in materials engineering, which gave me the necessary skills to understand materials failure and corrosion, both of which were applicable to land and marine based investigative work. Having specialised in both the criminal and civil fields, I found it interesting to make comparisons between the two systems. Both have many unique features but the one that really stood out to me was the way in which evidence is handled in civil work.

One of the most critical and fundamental concepts in forensic science is the Chain of Custody. Put simply, this is chronological paper trail recording; where the item came from, who handled it, its current location, and the location of all the supporting documentation to back all of this up.

When conducting criminal investigations, the chain of custody was very clear on all my cases. If a chain of custody was unclear, I understood the item was not admissible in court. Therefore, the paperwork was, and still, is extremely important.

In civil accident investigation cases, I noticed that this system was less rigorous, and I had to explain to clients that if and when the case went to court, establishing the provenance was critical.

Marine based investigations are, by far, my favourite type of case work. I love nothing more than taking a launch out to sea, boarding a vessel, finding a broken or corroded object, taking samples back to the laboratory, and figuring out what happened and why the object failed.

Writing a court compliant report and then providing expert testimony is the ultimate stage, and one I enjoy enormously. When you are invited to stand before the court, as an expert witness, you have the opportunity to talk to a room about a subject that fascinates you, and the best part is that everyone is forced to listen. Sometimes the questions posed by opposing counsel are challenging, but that is part of the job.

I have had several experiences in marine based case work where the sampling methods and samples themselves were questionable, which could compromise the chain of custody.

One of my favourite examples involved travel to a dry dock in Asia to inspect the hull of a vessel, which was damaged, and to determine the nature and circumstances of the crack and hole observed by the crew, i.e. who or what did it, and how.

When I arrived at dry dock, I was given access to the vessel and the crack damage, and I proceeded to mark out an area of the fracture surface that I wanted to have sectioned for later examination in the laboratory.

Normally, microscopic examination of a fracture surface can indicate the failure mode by identifying distinctive features along the surfaces of the material. After marking up the relevant areas of the crack, I was told that it was too dangerous for me to witness the steel containing the crack being cut out using an oxy-acetylene torch.

An hour later, I was presented with a large piece of metal from the hull of the ship. I asked which part of the crack it originated from but was informed that the crew did not know.

It transpired that my marked-out areas had indeed been cut out but sadly, had been dropped into the sea, which was rather unfortunately, 13 metres deep.

To avoid disappointing me, the crew decided that providing me with another random piece of the hull, in no way associated with the fracture, might suffice.

After realising my evidence had been lost, I asked if I could be provided with a magnet and a rope to retrieve my evidence from the seabed. It turned out there were no magnets or spare rope in dry dock, and there was insufficient time to find and instruct divers to find the pieces.

I persisted and was miraculously given permission to witness another attempt at removing more sections of the crack, along the fracture surfaces. During this time, I was told again to keep my distance for safety reasons and watched a welder wearing flip flops, light a cigarette with the acetylene torch before removing the pieces.

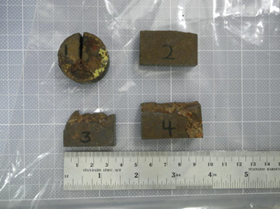

I travelled back to the laboratory, with 20kg of metal on my back and had the samples further sectioned down for the necessary tests.

I learned a very good lesson – I should always be present during any cutting/removal work in order to make sure that the correct samples are being taken. Thankfully, due to my persistent and pedantic nature, I was able to find out what happened and correct it, in this case, and secure the relevant evidence.

In addition to being present and involved with sampling methodology and its subsequent execution, we as experts in a marine context need to ensure that the samples reach the laboratory safely.

I mentioned carrying heavy metal previously, which you can do if it is considered safe and not breaching any health and safety regulations.

However, if the case material is a metal ore cargo, such as nickel or aluminium, this is not practicable. Metal ores are shipped in bulk carrier vessels, usually in cargo holds that can hold un excess of 20,000 tonnes of material. Bulk carriers can experience liquefaction of the cargo, in which the bulk materials can enter a liquid state, causing instability and sometimes capsize. When the cargo is observed to be in the early stages of liquefaction, and forensic engineers can sample the material on-board, and test it establish whether the cargo was safe to load.

Due to the nature and size of the cargo stored in each cargo hold, sampling quantities can vary between hundreds of kilograms to several metric tonnes. To maintain the chain of custody, I need to ensure that the samples are bagged, tagged, and transported appropriately. I have, in certain circumstances, sat with the bags of nickel ore in a truck to ensure that they reach their target destination.

While marine investigation work is excellent fun, experts need to be robust when it comes to overseeing sampling of material/cargo and transportation to the laboratory. I find it is best to communicate the importance of chain of custody from the outset, making it clear to the Master of the Vessel and the Ship Owners in advance that I wish to sample the broken/corroded material or cargo.

When I am finished with my inspection on board, I request either the Chief Officer or the Master to sign the chain of custody documentation to indicate that they have released the item to me.

When I arrive at the laboratory, I request the exhibit handlers on site to sign that they have received the items, allowing me to commence preparing a court compliant report, knowing that I have secured the provenance.

Finally, all I need to worry about is the science, my ability to convey it appropriately to the court, and of course how to maintain good decorum on Zoom. In these truly novel times, you worry about your bandwidth as much as your appearance and demeanour.

About the Author

Sophie is the Head of Marine at Hawkins and is based in our London office. In addition to her casework, Sophie regularly presents to law firms, P&I Clubs and loss adjusting companies on materials failure analysis, corrosion, and cargo/liquefaction matters. She is available 24/7 to discuss any urgent matters.