On 10 May 2002 the 12.45 Kings Cross to King’s Lynn train derailed just south of Potters Bar station.

Seven people died; six on the train and a pedestrian struck by debris. Numerous people were injured.

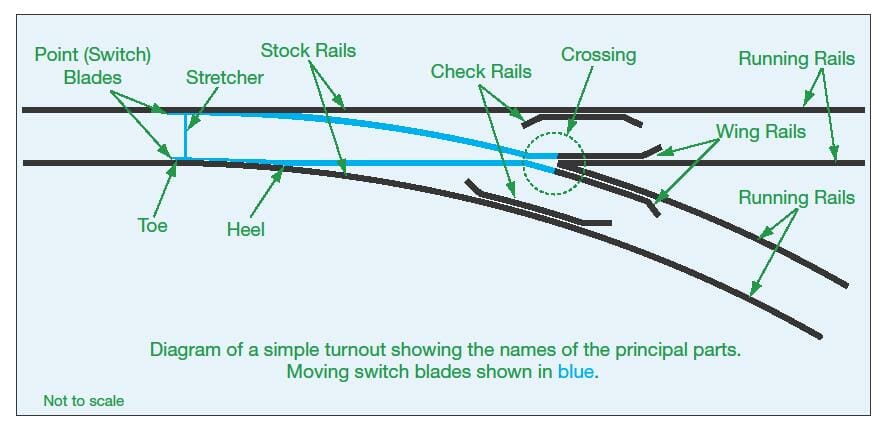

The train was travelling at 97 mph when the fourth and last coach derailed completely, separated from the remaining three coaches and rolled sideways onto the platform at Potters Bar station. It was quickly established that the cause of the derailment was the failure of a set of points just south of the station.

The derailment occurred because the points failed as the fourth coach was passing over them. The rear bogey (set of wheels) was forced from the down fast to the down slow line, swinging sideways and causing the coupling between the third and fourth coaches to fail. The fourth coach continued under its own momentum and rolled a number of times before becoming wedged under the canopy.

It was immediately apparent that the points had failed in a number of ways. The investigation centred on trying to explain how the points could have come to be in that condition, given the maintenance procedure defined by Railtrack. The points had last been inspected and tested on 1 May 2002 and a track patroller had walked over the points the day before the accident. If the points had been in a satisfactory condition on 1 May, could they have then failed with no warning 9 days later?

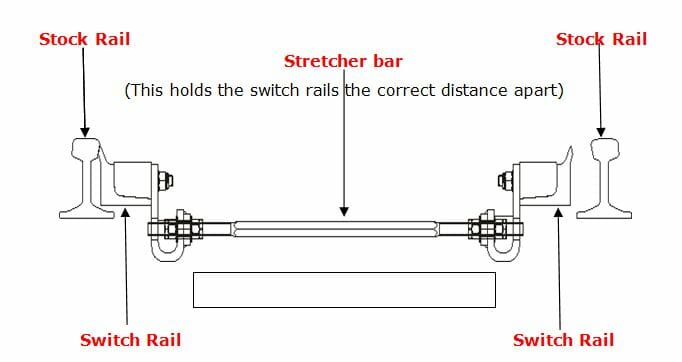

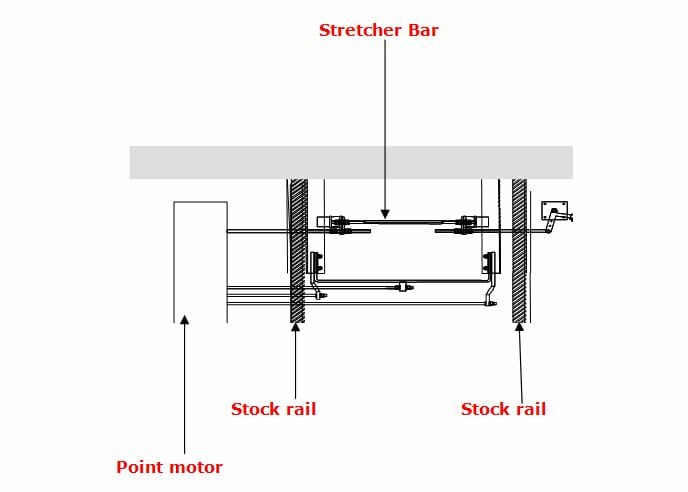

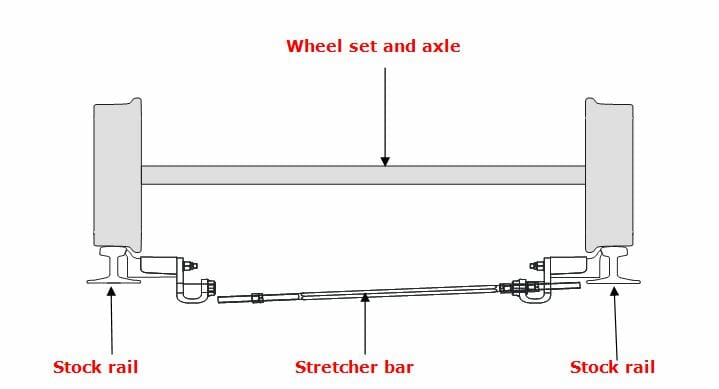

The switch rails (the moveable parts of the points), which separated during the derailment, should have been held at a constant spacing by an adjustable stretcher bar.

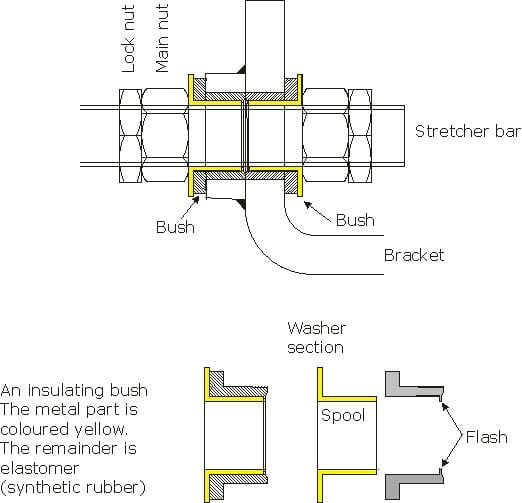

The stretcher bars were secured using lock nuts tightened across rubber insulating bushes.

Insulation is required because of a system used for the detection of the position of trains. Most of the railway network is divided into sections with each rail insulated from its partner. When a train passes into a section, the metal wheels and axles complete an electrical circuit, so that a current passes between the rails and the presence of a train is registered. Because the stretcher bars are connected to both switch rails, which in turn are connected to or come into contact with the fixed rails, the two switch rails must be insulated electrically from each other.

The points machine includes detection and locking mechanisms which ensure that the switch rails are in the correct position and are locked. If the mechanism in the points machine does not detect that the switch rails are in the correct position and locked, the signaller cannot set a route to cross the points. The points fail safe in that any problem causes a ‘points failure’ and trains are not allowed to pass over the points until it has been investigated.

SO HOW DID THE ACCIDENT AT POTTERS BAR HAPPEN?

Jarvis Rail was responsible for the maintenance of the section of the network on which the derailment occurred and Hawkins was instructed by Jarvis to investigate the cause of the derailment. Jarvis’ internal investigation showed that all of the scheduled maintenance had been carried out and the points had no significant history of problems.

Jarvis’ further investigations revealed that at the last test, on 1 May, a lock nut pair at the right hand rear end of the points had come off. One of the technicians put them back on and tightened them as hard as he could.

The technicians inspected the remaining nuts and bushes around the points and found that they were all ‘ok’, except that one of the insulating bushes on a stretcher bar had ‘perished’ and would need to be replaced. That was not considered to be critical because the bush at the other end of the stretcher bar was in good condition, maintaining electrical separation. The replacement could be factored into the routine maintenance and did not require the points to be taken out of use.

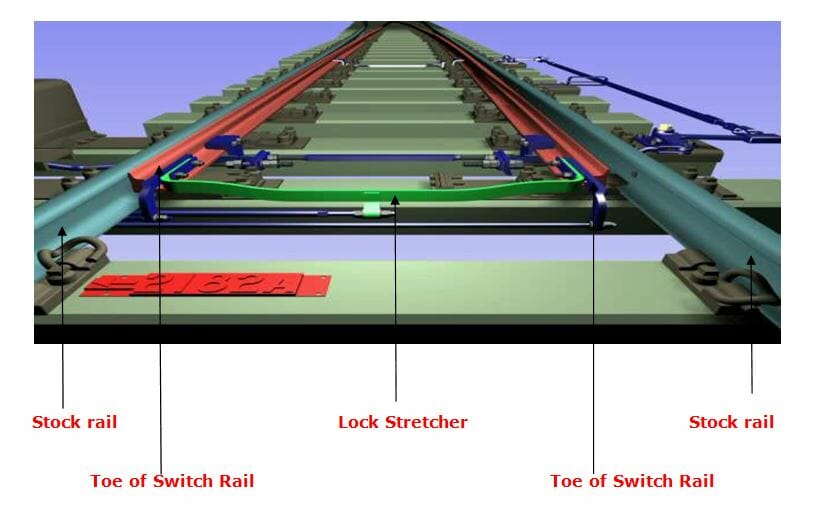

After the derailment the same nut pair was found to be detached from the stretcher bar and the corresponding bush was very badly damaged and had also come off the stretcher bar. A similar set of nuts and a bush at the left hand end of the front stretcher bar had also come off and the bar was displaced to one side. This meant that neither stretcher bar was restraining the switch rails.

For the switch rails to separate, a third component, the lock stretcher, also needed to have failed. The lock stretcher is a bar linking the two tips of the points and was indeed found to have broken.

The lock stretcher was the component to which the various detector rods were attached and was not designed to take the load imposed during switching the points. It could do so for a while, but with the loss of the two stretcher bars its failure was inevitable. Critically, the only warning that the points were failing would come from the detector rods and since these were attached to the lock stretcher, which remained intact right up to the derailment, no warning was given.

The investigation carried out by HSL concluded that only one nut had been replaced on the right hand rear stretcher bar, not two, as suggested by the technician. Also that the front stretcher bar had been moved as far as possible to the right, with only one nut and no bush present on the outside of the left hand end. The reasoning behind these conclusions was complex, but depended on assumptions about how quickly nuts could loosen and also the interpretation of marks on the stretcher bar and brackets.

If the HSL’s observations were correct, then Jarvis technicians must have left the points in a dangerous condition and then falsified the records. The technicians denied doing so and Jarvis claimed initially that the failure was caused by sabotage, something that had been know to happen on previous occasions.

Loose nuts on stretcher bars could move astonishingly quickly and the condition of the insulating bushes was critical to the question of whether correctly tightened nuts could become loose. Our findings were tested in a collaborative exercise between Network Rail, the Railway Safety and Standards Board, HSE/HSL, British Transport Police and Jarvis.

The tests showed that ‘properly tightened’ nuts on stretcher bars with bushes in good condition did not come loose. An important point to make here is the expression ‘properly tightened’.

The rail industry uses “Group Standards” which define procedures to be followed in installation, maintenance, testing and operating the railways. However, there was no Group Standard for assembling stretcher bars. The significance of the procedure for installing stretcher bars, specifically tightening the nuts, appears to have been overlooked by the designer of the points and then by those responsible for defining the procedures (Railtrack). Specifically, the vibration dampening role of the insulation material in the bushes had not been appreciated.

The insulation material of the bushes degrades with time and compressing the bushes heavily will increase the speed of degradation. Although the primary function of the bushes was electrical insulation, they also dampened the vibration transmitted from the rails to the stretcher bar and to the nuts. When the bushes degrade the dampening effect is reduced. Therefore, more vibration is transmitted to the stretcher bar and nuts.

The technicians who had replaced the nuts nine days before the accident noted that the bush had perished. However, the potential significance of this was not known and therefore such a fault was not considered critical by anyone. We found in our tests that if perished bushes were simulated, nuts could loosen. If nuts could loosen, they could move. If they could move, then the control of the position of the switch rail could be lost.

The conclusions from our investigations were:

> The design of the points had not taken into account the properties of the insulating bushes and the effect that this would have on other components.

> As a result appropriate installation and maintenance procedures were not developed.

> There was no evidence to suggest that Jarvis’ technicians did not maintain the points to the standards defined by Railtrack. However, that standard was lacking in several important aspects.

Although their involvement was brought to an end by Jarvis going into administration, Rod Newbery and David Newland continued the work and finished the investigation at Hawkins’ expense and then sought permission to give evidence at the two-month Inquest into the derailment because of the importance of their findings to public safety. Their evidence was well received by the Coroner and was referred to on numerous occasions during the Coroner’s summing up and in the later Narrative Verdict produced under Rule 43 of the Coroner’s Court.

This case study is necessarily truncated, but the information from our studies is in the public domain, having been reported at the Inquest. A much more detailed case study or a presentation on the subject may be obtained by contacting us.

Hawkins has investigated numerous railway accidents such as:

- Paddington

- Selby

- Hatfield

- Tebay, Cumbria