Benedict Barron

Dr Benedict Barron: Hawkins’ Fires & Explosions, Contamination & Pollution expert. Ben graduated from his PhD in Chemistry from Imperial College, London.

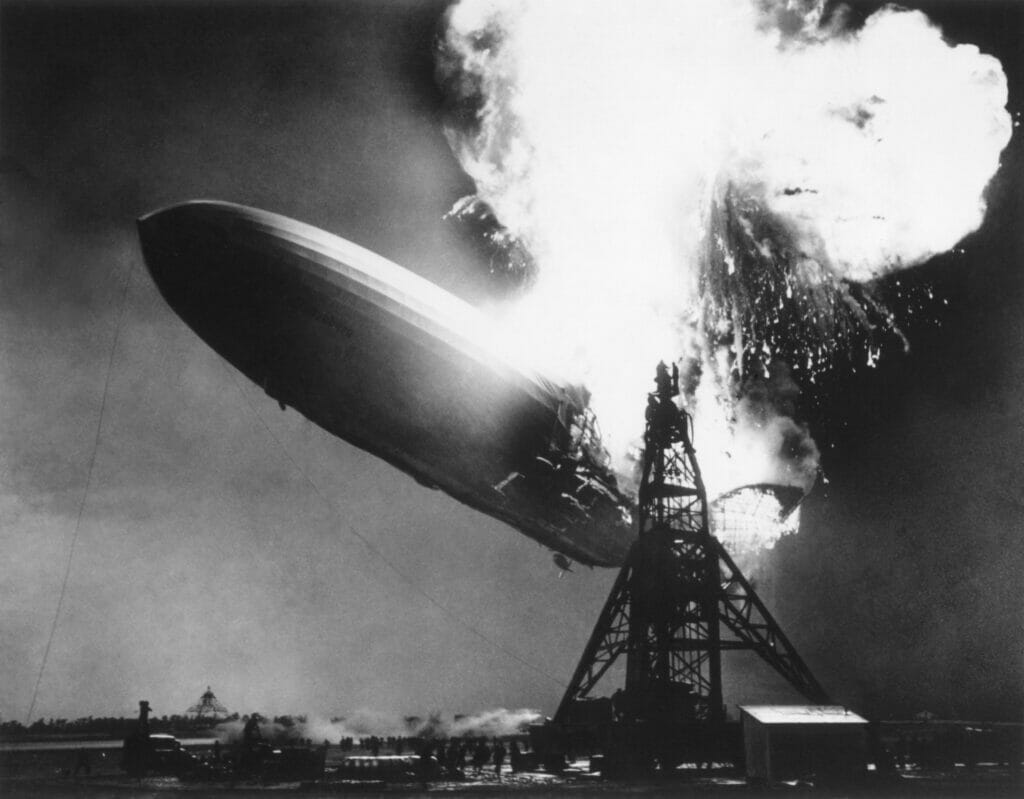

Materials Series – The Effects of Hydrogen on Materials Properties

Lin introduces the basic characteristics of hydrogen, the current trend for its applications, its effects on materials, and some recent examples of materials failures in the context of insurance claims.

Materials Series – Fibre Reinforced Composite Pipes & Tanks

Amir explains what a fibre reinforced composite is, where they are used, and some of the methods for manufacturing pipes and tanks made from composites.

Materials Series – Leaking Pipes & Cylinders

Philippa explores common themes that lead to leaks and failures in high-integrity industries, or the pipework in your home.

Hawkins Webinars: The Materials Series

Learn from Hawkins’ on failures in gas turbines, the effects of hydrogen on materials, spontaneous glass fractures, common leak causes and more.

Materials Series – Sprinkler Systems and the Potential Problems

A review of sprinkler pipework including, commissioning processes, material compatibility and what can go wrong.

Materials Series – Inclusion Conclusion

Glass is often thermally toughened, and whilst this imparts strength it can also leave it vulnerable to fracture by debris from manufacture; inclusions. Elly will discuss types of glass and the manner in which they fracture.

Materials Series – Failures Encountered in Aeroderivative Gas Turbines

Stephen gives insight into what an aero-derivative is, as well as their benefits and disadvantages. He also discusses RCA methodology

and damage mechanisms encountered.

Stephen Rowbotham

Stephen is enthusiastic about providing solutions to issues faced by clients in the changing business environment and the goal of achieving net zero power generation.

Hawkins Welcomes Materials Expert Stephen Rowbotham

Hawkins would like to extend a warm welcome to materials expert, Stephen Rowbotham.