Dr Paul Moody Featured in Institution of Power Engineers Journal

Dr Paul Moody, reviews oil-fired boilers in the March edition of the Institution of Power Engineers Journal (IPowerE).

Hawkins Spring Drinks Reception

Hawkins would like to invite clients and colleagues to our Spring Reception in Manchester. We will be hosting several short CPD presentations followed by a networking reception with drinks and canapes.

Sophie Parsons

Sophie is a Chartered Engineer (CEng) and a Fellow of the Institute of Materials, Minerals, and Mining (MIMMM). She received her BEng and PhD (Eng) from Queen Mary College, University of London in Materials Science & Engineering. After a post-doctoral research post at Queen Mary’s, she joined LGC Forensics, UK, as a Forensic Chemist, specialising in the examination of textile fibres and polyurethane foam retrieved from crime scenes. During this time, Sophie analysed trace evidence, prepared detailed technical reports for court and presented evidence in court as a Court Reporting Officer. Following her arrival in Hong Kong, Sophie worked as a Research Fellow at City University, Kowloon Tong, developing techniques for analysing trace material evidence in crime laboratories. In 2012, Sophie joined Hawkins’ Hong Kong Office, and has since provided expertise in materials failure analysis, corrosion incidents, and contamination incidents in both the marine and land-based sectors. As a materials engineer, Sophie has conducted investigations involving the failure/corrosion of glass, ceramic, plastic and metal, and is particularly experienced at investigating lift and wire rope failures and criminal work involving trace evidence. For contamination incidents, Sophie can assist in determining the impact and extent of exposure to fresh water, salt water, […]

Nico Zurcher

Prior to becoming an investigator, Nico worked in a international environmental consultancy where he was involved in a number of major government marine projects in Hong Kong, as well as oil and gas, and mining projects around Asia. In 2011 he joined HFS-Asia in Hong Kong, where he worked as a fire investigator and consulting scientist. In 2015, Nico moved to London where he joined Hawkins to bolster our growing International and Shipping Incidents team. He continued investigating a broad range of land-based and marine incidents, both in the UK and internationally. He was also a member of our contamination team, taking on cases in the UK and Europe. Hawkins acquired HFS-Asia in 2016 and in 2020 Nico returned to Hong Kong to head the office he helped to build several years earlier. Nico has investigated several fires in large industrial plants, as well as in commercial and residential premises. On the marine side, he has investigated major fires on container and general cargo vessels. He has worked on numerous cases of bulk cargo spoilage, involving grains, oil seeds and seedcake. Nico has also worked on cases involving the carriage and storage of mixed chemical cargoes, and the contamination of […]

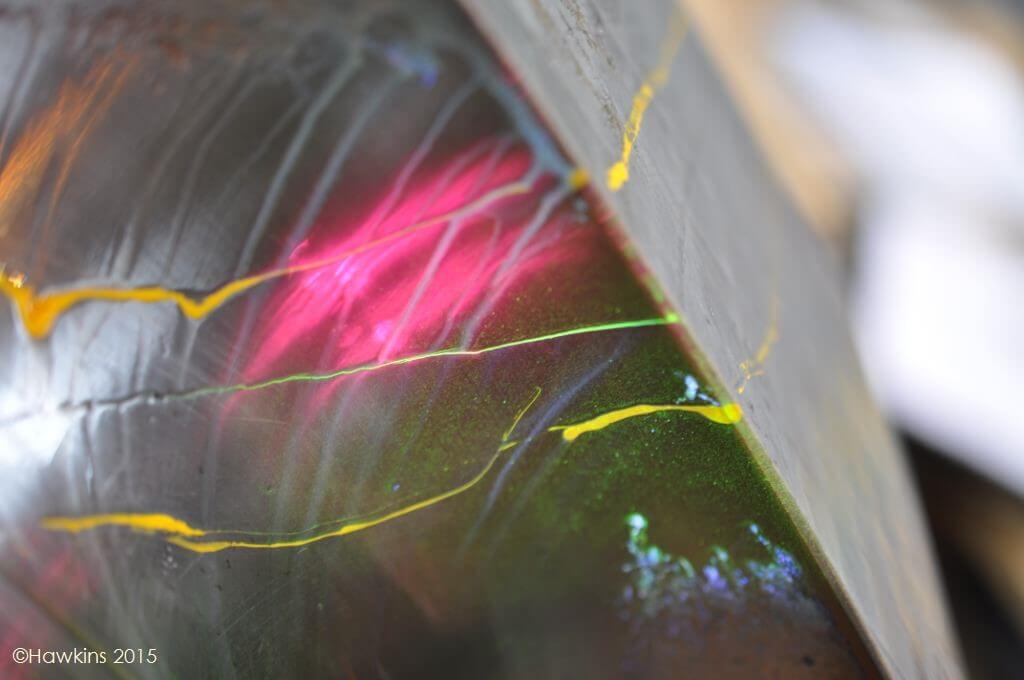

Cracking Up: Common Causes of Fracture Related to Pre-Existing Features

Sometimes a fracture is mildly irritating, leading to cosmetic impairment or slight loss of functionality. However, fracture can also lead to catastrophic failure, which can cause inconvenience, expense, or in the worst case, loss of life.

Hawkins Winter Events Round-Up

Hawkins attended over 70 different conferences, seminars and social gatherings, we welcomed 17 new experts to the business, and we hosted our annual winter receptions in London, Dubai, Singapore, and Hong Kong, allowing us to spend time with clients in person.

Hawkins Latest Webinars

Join our experts as they present on topics which include the challenges faced while investigating failures within the power industry, and the many issues that can arise through improper consideration of acoustics, noise and vibration.

Hawkins Adds Five Top-of-the-Range HIROX Microscopes to its Laboratories

Hawkins is pleased to announce the arrival of HIROX RX 100 microscopes to five of our UK laboratories.

Hawkins Welcomes Chemical Engineer Sam A’Court

Hawkins is delighted to welcome Chemical Engineer, Sam A’Court , to our Reigate office.

Hydrogen Embrittlement – how can a gas make a metal brittle?

Hydrogen, from its explosive potential to its benign, life giving properties after reacting with oxygen, is one of the most dynamic elements.

Italiano

Italiano