Geothermal

Geothermal power plants use steam from hot water found below the earth’s surface to rotate a turbine that activates a generator, so producing electricity. In the transition from fossil fuels, geothermal energy is one of the renewable energy systems that can provide a base load supply for either local heating networks or power generation.

The type of geothermal energy available is dependent on the local geology. Most areas can be supplied with systems that can provide sufficient heat for local homes and buildings. In areas with a more active geothermal resource, full power generation from binary and flash units can be built and operated.

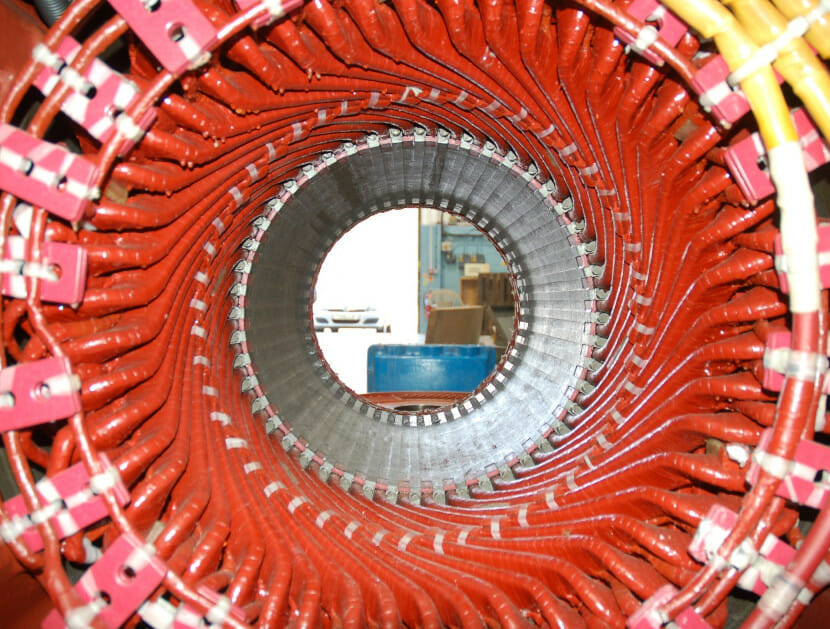

Flash power plant units are based on nuclear rotors. The geothermal rotors work in aggressive steam conditions with carryover of silica and other rare earth elements. Mineral deposition and moisture damage can affect the turbine efficiency, leading to generation losses. In low temperature steam, the use of binary plants/heat exchange are employed. In binary plant, the area exposed to the aggressive steam is the heat exchange tubing and as such, cleaning and inspection is critical as scaling can occur.

WHY APPOINT A FORENSIC INVESTIGATOR?

Our team of experts have both the expertise and practical experience to impart the best practice guidance in this sector to reduce the risk of failure.

Geothermal power systems rely on the use of steam/hot water generated by the heat within the Earth’s crust and, as such, the working media is significantly more aggressive than conventional steam systems. This results in more issues with corrosion and scale formation, which affects the availability and utilisation of the power generation asset or heat exchanger unit.

If a failure does occur, Hawkins can assist you in identifying the root cause of the issue and support you in returning the asset to service as quickly as possible.

Examples of Typical cases

The list below provides a few examples of the types of issues that we can investigate:

- Failure of heat exchanger tubing following cleaning.

- Geothermal blade and diaphragm failures.

- Bearing failures.

- Binary plant issues.

- Heat exchanger failures.

- Generator issues.

- Balance of plant issues including cooling towers, cooling fans and pumps.

- Issues with steam separators and scrubbers.

- Corrosion under insulation.

- Advice on preservation and repairs.

If you would like to discuss how we can assist you please fill out our enquiry form or call us for a free consultation.

HOW DOES HAWKINS INVESTIGATE FAILURES IN GEOTHERMAL ENERGY EQUIPMENT?

When Hawkins is requested to investigate an issue we employ in-house methodology built from over 40 years of experience. This enables all Hawkins investigators to provide a consistency of service and product. The methodology comprises three steps:

1

Consultation

On receipt of the enquiry, we discuss with the instructing party what happened, and when it happened and request a suite of data covering the operation and maintenance of the asset during its operating life. This collected data may include video coverage showing the operating conditions in the plant, before and during the event. We may also interview personnel present at the time of the event to get an insight into the timeline of events before, during and after the event.

2

Inspection

Following collection of all the data and completion of the consultation, Hawkins engineers will travel to the site or repair shop to inspect the asset. This will enable us to assess the extent of the damage, and identify the source of the failure. This step can be completed on-site, or may require samples to be removed and examined in one of our laboratories.

3

Reporting

On completion of the inspection, a detailed report will be issued summarising the work completed and the findings of the investigation. This can include advice on operational and inspection changes to implement to minimise future events if relevant.

SPEAK TO ONE OF OUR EXPERTS

Testimonial

“Thank you for your superb effort in this case.”

Rhys Phillips

“Many thanks for turning out today at such short notice and providing the benefit of your expertise and knowledge. It was evident the Client was extremely relieved that this matter was being investigated expeditiously.”

Chaz Winterton

“I just wanted to say thank you for all your help and the information you found was of real insight. Thank you again for all your help.”

Stewart Hargreaves

“I just wanted to say thank you for all of your hard work preparing the Hawkins report. Please pass on my thanks to the rest of the team. We really appreciate the hours you have all put in and I know the client is pleased with your work.”

Philippa Jones

“I have recently needed structural engineering opinion on one matter and geotechnical engineering opinion on another. I experienced the usual difficulties with traditional providers of those services – excessive cost, inability to get on site quickly etc etc. When turning to Hawkins the contrast was clear – economical pricing, fantastic turnaround times, and really helpful reports that focussed on my needs without me needing to spend ages spelling it all out.”

Hawkins client

Related areas of expertise

Power & Energy

Hawkins' power experts have experience of forensically investigating losses worldwide on a wide range of power generation equipment from traditional thermal and nuclear power plants through to wind, hydro and solar generation as well as emerging technologies such as battery and flywheel installations.

Metallurgy

Losses involving metallurgical failures occur in a wide range of industrial and domestic environments and can lead to high value claims or even loss of life.

Chemical & Process Engineering

Chemical Engineering and Process Engineering are essentially interchangeable terms, whether it is engineering chemistry to make a desired product on the industrial scale for example a pharmaceutical drug or a beer or simply process materials for some beneficial purpose for example in water treatment or renewable power generation.

Hydro Power

Hydro power generation was the first green renewable energy and battery storage facility. Hawkins forensic investigators have completed numerous investigation into hydro power plant failures.