Transformers & Electrical Systems

The electrical systems are the life blood of most industrial processes. In power generation facilities, the busbars and cables take the power from the generators, via transformers and switchgear, and into the national and international transmission and distribution systems.

The impact of lost generation from the main transformer or switchgear on a site can lead to large repair costs, and lost generation or business interruption costs stretching into many millions.

Electrical equipment can have large amounts of power flowing through their conductors, but in the event of a fault, can have the potential to draw enormous amounts of energy from the grid systems. For example transformers have the potential to explode, igniting their insulating oil and causing extensive fires.

Switchgear in some instances will not have sufficient barriers in place to prevent the fault energy from being contained within the equipment (known as an arc flash) and again, providing a risk to personnel.

An important part of safely running electrical systems relies on the correct design of the equipment, based on fault analysis, and the correct electrical protection systems being installed and maintained.

WHY APPOINT A FORENSIC INVESTIGATOR?

Our team of experts have both the expertise and practical experience to impart the best practice guidance in this sector to reduce the risk of failure.

If a failure does occur, Hawkins can assist you in identifying the root cause of the issue and support you in returning the asset to service as quickly as possible.

- We have decades of experience working as operators of power plants or providing expert advice to them, from new build, operation, life extension to end of life.

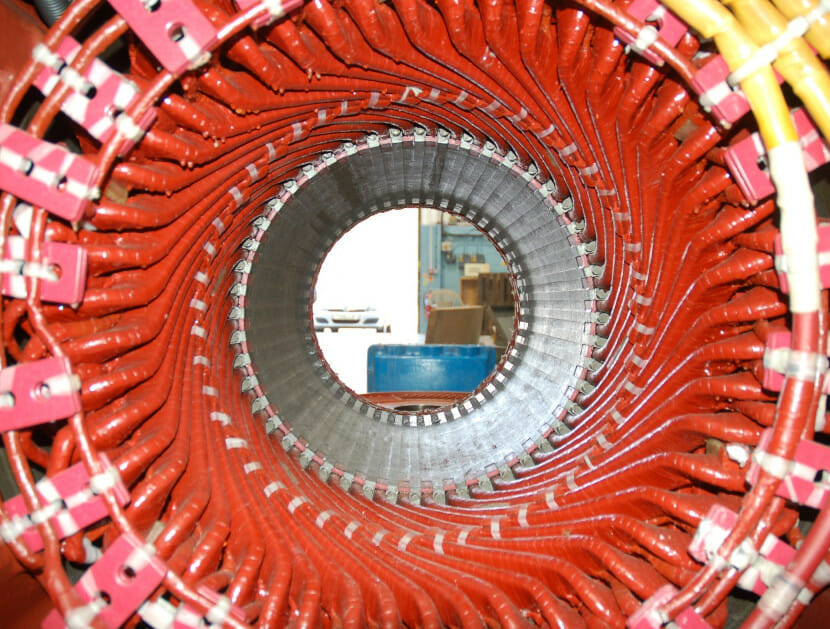

- Our experts have decades of experience on working with transformers, cables, switchgear, tap changers and all other electrical equipment.

- We are able to carry out reviews of system fault levels, protection studies and arc flash assessments.

We can analyse the high speed data recorded by protection systems following a fault. - We can advise on international best practice for the operation and maintenance of electrical systems.

- Support with analysis of condition monitoring and test results including reviewing transformer oil analysis.

- Our experts are well versed in all areas of electrical systems and have carried out failure analysis on all types of electrical equipment in various industrial settings.

- We have a deep understanding of international best practice for electrical plant operation and maintenance.

- We can support subrogation / recovery efforts.

- Can help you make decisions regarding where legal responsibilities and liabilities lie.

- We have provided court reports and given evidence in international court cases.

- We provide consultancy advice to prevent similar events.

- We can support the repair and restoration of electrical equipment. Suggesting repairs and service providers.

Examples of Typical cases

The list below provides a few examples of the types of issues that we can investigate:

- Transformer failures

- Bushing explosions

- Failure of On Load Tap Changers (OLTCs)

- Failures involving switchgear

- Arc flash assessments

- Failure of protection systems

- Cable failures

- Busbar failures

If you would like to discuss how we can assist you please fill out our enquiry form or call us for a free consultation.

HOW DOES HAWKINS INVESTIGATE ELECTRICAL SYSTEM FAILURES?

1

Consultation

On receipt of the enquiry, we discuss with the instructing party what happened, and when it happened and request a suite of data covering the operation and maintenance of the asset during its operating life. This collected data may include video coverage showing the operating conditions in the plant, before and during the event. We may also interview personnel present at the time of the event to get an insight into the timeline of events before, during and after the event.

2

Inspection

Following collection of all the data and completion of the consultation, Hawkins engineers will travel to the site or repair shop to inspect the asset. This will enable us to assess the extent of the damage, and identify the source of the failure. This step can be completed on-site, or may require samples to be removed and examined in one of our laboratories.

3

Reporting

On completion of the inspection, a detailed report will be issued summarising the work completed and the findings of the investigation. This can include advice on operational and inspection changes to implement to minimise future events if relevant.

SPEAK TO ONE OF OUR EXPERTS

Testimonial

“Thank you for your superb effort in this case.”

Rhys Phillips

“Many thanks for turning out today at such short notice and providing the benefit of your expertise and knowledge. It was evident the Client was extremely relieved that this matter was being investigated expeditiously.”

Chaz Winterton

“I just wanted to say thank you for all your help and the information you found was of real insight. Thank you again for all your help.”

Stewart Hargreaves

“I just wanted to say thank you for all of your hard work preparing the Hawkins report. Please pass on my thanks to the rest of the team. We really appreciate the hours you have all put in and I know the client is pleased with your work.”

Philippa Jones

Related areas of expertise

Power & Energy

Hawkins' power experts have experience of forensically investigating losses worldwide on a wide range of power generation equipment from traditional thermal and nuclear power plants through to wind, hydro and solar generation as well as emerging technologies such as battery and flywheel installations.

Electrical Engineering

With the prevalence of electrical and electronic devices in the modern world there is considerable scope for failures to occur. These can range from the failure of a single electronic component to failure of multi-megawatt power plants.

Hydro Power

Hydro power generation was the first green renewable energy and battery storage facility. Hawkins forensic investigators have completed numerous investigation into hydro power plant failures.

Geothermal

Geothermal power systems rely on the use of steam/hot water generated by the heat within the Earth’s crust and as such, the working media is significantly more aggressive than conventional steam systems. This results in more issues with corrosion and scale formation which affects the availability and utilisation of the power generation asset or heat exchanger unit.