In recent years, Hawkins has increasingly been asked to investigate escapes of water originating from chlorinated polyvinyl chloride (CPVC) pipework. CPVC is a type of thermoplastic that was introduced for potable plumbing in 1959 and is now also extensively used in fire suppression systems, gaining safety certification in the UK, USA and Canada in the 1990s.

However, Hawkins has investigated a number of incidents where CPVC pipes (from various manufacturers) have been used in conjunction with incompatible fire-stopping compounds. Fire‑stopping compounds are often used to seal the gaps around pipes (or other services) where they pass through fire-walls. Using the incorrect compound to seal these gaps appears to be of growing concern throughout the industry and a number of CPVC pipe manufacturers have produced guidance documents listing proprietary fire-stopping products that are not compatible with their pipework. Limited information is currently available with regards to what specific chemical species are causing this incompatibility. However, some incompatible products have been found to cause pipework to become more flexible, whilst others have caused pipework to become brittle.

The FBC System Compatible Program[1] is a resource made available to manufacturers of ancillary products intended to be used with CPVC to help determine whether a product is chemically compatible; note that only the brand names are given, and not the specific chemical species.

There are many different CPVC pipe manufacturers, and whilst the bulk of the material used to make the pipe will be CPVC, each manufacturer may add their own blend of fillers and pigments. For example, it is common for CPVC pipework used in sprinkler systems to be orange in colour, whereas pipework used for hot and cold water distributions systems is typically black or dark brown. Changing the colour, means changing the ingredients used to make the pipe. These ingredients will determine how the pipe reacts in the presence of certain chemicals.

In general, there are two mechanisms that may cause failure of CPVC pipework when used as water distribution systems in conjunction with fire-stopping compounds. I provide a brief description of each below, and give examples of visual indicators that may occur prior to failure, and so might help prevent an escape of water from occurring. It should be noted that both mechanisms are time‑dependent, and problems can still occur either weeks, months or years after installation.

PLASTICIZATION, SOLVATION AND SWELLING

The interactions between liquid chemicals and polymers can be understood through the use of the Hildebrand Solubility Parameter (δ). This parameter provides a numerical estimate of the degree of interaction between materials, and can be a good indication of solubility, particularly for plastic materials. Essentially, materials with similar δ values are likely to be miscible, meaning that they will fully dissolve in each other.

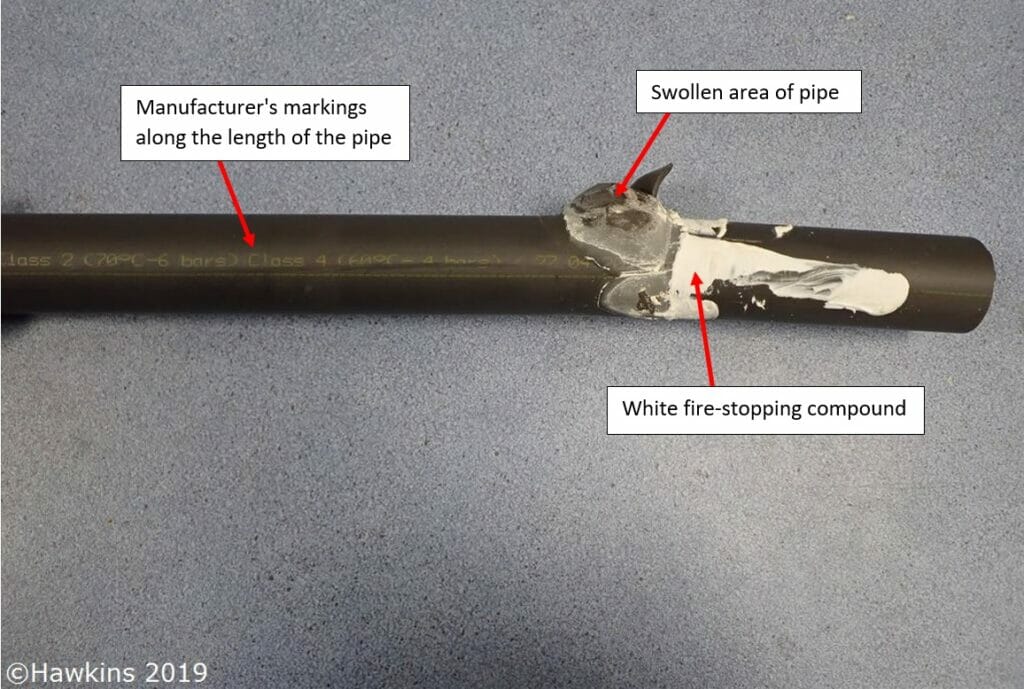

Plasticization of pipes occurs when chemicals are absorbed into the polymer, interacting with the molecular chains that make up the polymer. This can cause the polymer to lose its rigidity and soften. When this happens in CPVC, the polymer swells. Where it is used as pipework for a water distribution system, the internal pressure of the water can push the softened area of the pipework outward, resulting in a ‘bubble’ type appearance, which can eventually rupture.

In the case illustrated above, to determine what chemical caused the pipe to soften, I took samples from both ruptured and non-ruptured areas and analysed these using a technique called Fourier-transformation infrared spectroscopy (FTIR). This technique uses infrared radiation to identify organic and inorganic compounds within a material. In this case, I found that the bulk of the pipe was made from CPVC, calcium carbonate and titanium dioxide filler. Although these compounds were also present in the ruptured area, there was also a high concentration of another material, known as an ester, which was also present in the white fire-stopping compound used around the pipe. It is likely that this ester is what caused the pipe to soften and swell.

ENVIRONMENTAL STRESS CRACKING (ESC)

Internal stresses may exist in the body of the plastic before it is exposed to an external environment. These stresses are often produced during the manufacturing processes and are often referred to as residual or frozen-in stresses. In chemical environments, the interaction of residual stresses and chemical compounds can lead to a phenomenon known as environmental stress cracking, or ESC.

In the case of thermoplastic pipes, such as CPVC, manufacturing typically involves the plastic being extruded into a tubular form, which is then cooled with water, allowing the plastic to solidify into its final shape. The cooling process inevitably produces a temperature gradient across the thickness of the pipe, generating frozen-in residual stresses, both circumferentially and along the length of the pipe.

Pipework will also be subjected to stress when in use. I have investigated cases where CPVC pipes have a ‘snaking’ deflection caused by installation. Most manufacturers will specify a maximum allowable deflection, although this is only applicable when no chemically aggressive agent is present.

When pipes are used either for the supply of hot/cold water, or as sprinkler pipes in fire suppression systems, there will be stresses on the inside of the pipework caused by the pressure of the water.

Several physical characteristics are typical of ESC:

- Failure is always non-ductile

- Brittle fracture is surface initiated

- The crack initiation surface was in contact with an aggressive chemical

- The polymer was mechanically stressed

The above photographs show ESC of a CPVC pipe used as a sprinkler pipe. As with the previous case, I used FTIR to determine what had caused the pipe to rupture. I found the bulk of the pipe was made from CPVC and a titanium dioxide filler, i.e. it lacked the calcium carbonate of the previous case, and the ruptured area again exhibited high concentrations of an ester. In this case, the ester had caused the pipe to become more brittle, highlighting how a variation in the compounds used to make the bulk of the pipe can affect how it fails in the presence of the same type of chemical.

INDICATORS OF CONTAMINATION

There are a number of visual indicators that can be used to help determine if a CPVC pipe has been contaminated with an incompatible compound. The first step is to identify the pipework as CPVC. There are typically markings along the length of the pipe, which will state it has been manufactured from CPVC. There may also be markings on the pipe indicating what pressure it is rated to, as well as the identity of the manufacturer.

If pipework passes through a fire-wall, this is typically a good indicator that some type of fire-stopping material has been used around the pipe where it passes through the wall. In most circumstances, the use of a fire collar negates the requirement to apply additional fire-stopping compound onto the pipe itself.

Using insulation sleeves around pipes in these areas is also common, although fire-stopping compounds are often also used in conjunction with these sleeves.

In some instances, I have found that fire-stopping compound has been applied to the pipework as well as the sleeve. An initial visual examination of these areas is often beneficial. If the pipe is swollen or cracked in this area, this is a cause for concern, because it is likely that the compound used was not compatible. It is also possible that fire-stopping compound has been applied underneath the insulation sleeve. This can often be visually identified if the insulation sleeve does not have a uniform appearance around the circumference of the pipe. If this is the case, the insulation sleeve should be removed and the condition of the pipe inspected.

The gap created by a pipe running through a fire-wall will require some form of plug, so as to seal the penetration; this is commonly done using a fire-stopping compound. These pipes should be inspected where possible to ascertain whether the compound has caused any damage to the pipe, as well as, whether these sections should be removed (if this is the case), and replaced using a compatible fire-stopping compound. Where pipes have been installed in difficult to reach areas, it is often the case that a fire-stopping compound has been used, as it is easier to apply than installing either a fire collar or an insulating sleeve.

It should also be noted that the temperature of the water within the pipe will affect the rate at which contamination will occur; generally pipes carrying hot water will be affected more quickly than those carrying cold water.

Unfortunately, it is not always possible to determine if the fire-stopping compound used is compatible with the pipework. A visual inspection should help determine if damage to the pipe has begun (either by ESC or plasticization), but a visual inspection may not always provide a definitive answer. Because both of these mechanisms are time-dependent, and in the case of ESC, can often occur with little or no warning, the most advisable course of action is to ensure a compatible compound is used in conjunction with the manufacturer’s guidelines at the time of installation.

ABOUT THE AUTHOR

Dr Christabel Evans is a Materials Engineer who specialises in material failures. Within Hawkins, Christabel has carried investigations into the failures of polymers, metals, glass and composites, escapes of water and oil, mechanical system failures and personal injury claims. She is based in our Glasgow office.