Last month, members of our Fire, Power, and Engineering teams gave a technical presentation to RSA Insurance Group at DAC Beachcroft’s Manchester Office.

Electrical Engineer Ben Lister began the presentation by discussing Widespread Issues in UK Renewable Energy. He explained that the three most common issues in the modern renewable energy industry are defective components, environmental impacts, and maintenance.

Reviewing a case study involving switchgear bushings from a particular manufacturer, Ben explained that after passing necessary IEC (International Electrotechnical Commission) tests, 33kv bushings were being used to connect solar farms to the National Grid. However, several bushings from the same batch failed after approximately the same length of time in service, resulting in the manufacturer changing the test regime for all new batches. He went on to describe a similar case involving connectors from another manufacturer. Inspections at the wind farms where they were being used revealed problems with partial discharge resulting in a reduction of service life. Due to this, the manufacturer recommended replacement with a newer model at the earliest opportunity.

In relation to the UK environment, Ben gave an example of good design when it comes to solar farm ‘indoor’ substations. He explained that a ‘good design’ would usually consist of adequate drainage, covered ventilation, and the substation being raised from the ground and sealed. However, many in the UK are just converted shipping containers meaning that heating, cooling, and dehumidification are not always provided.

Concluding with maintenance practices, Ben explained that the maintenance of parts is usually contracted out to independent companies sometimes resulting in variable levels of standards and practices, due to issues with experience, motivation, and cost pressures. The result is a detrimental effect on renewable energy in the UK.

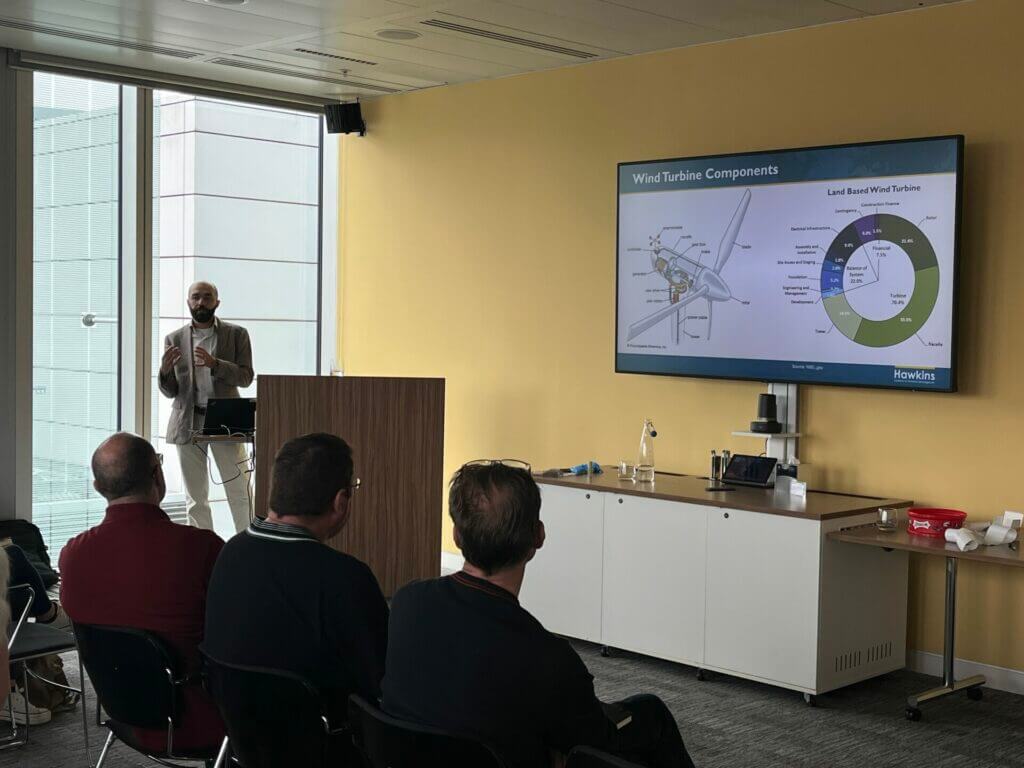

Materials Engineer Dr Amir Hajdaei presented Wind Turbines and Associated Failures. Amir discussed the various components of wind turbines, common failures, blade structure, fatigue and condition monitoring. Part of his presentation also analysed wind power capacity and trends. He stated that a 12MW turbine costs around £8 million excluding infrastructure and installation costs, and so ensuring that these are in the correct condition and working properly for as long as possible, is imperative to mitigate failure resulting in business disruption and further costs. Amir explained some common types of wind turbine failures often include electrical failures (e.g. control systems, busbars, transformers), and mechanical failures (e.g. gearbox, yaw system, generator), as well as nacelle, blade and tower failures. Amir went into more detail on blade failures highlighting that the most common incidents result from component failure, lightning strikes, adverse weather conditions (high winds), accretion of ice/snow, poor maintenance and human error.

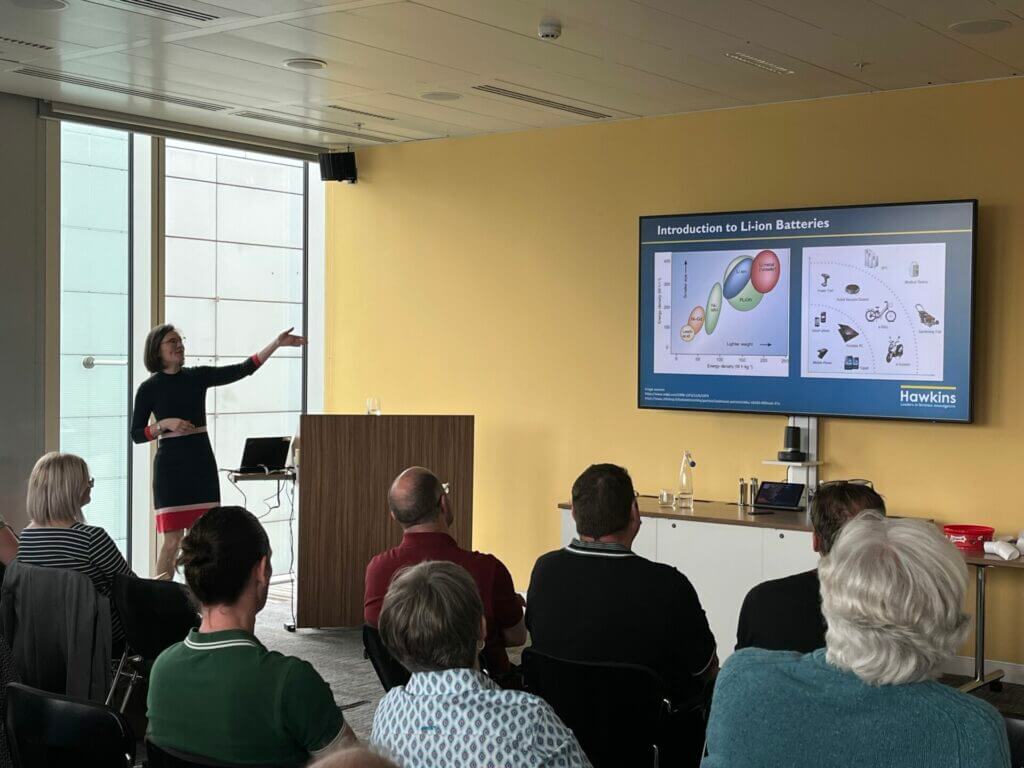

Mechanical Engineer Marie Hayward followed Amir with her presentation on Lithium-ion batteries. A hot topic at the moment, Marie gave an introduction to Li-ion batteries including their design, construction and operation. She discussed the common failures and their causes, as well as the process she would undertake for the investigation of a Li-ion battery fire.

Marie advised that at present Li-ion batteries have the highest charge density of any comparable system, meaning they can provide a lot of energy relative to their weight. Marie explained that there are two common types of failure: non-energetic failure and energetic failure (thermal runaway). Non-energetic failure occurs in all batteries and is part of the normal life cycle. This usually results in things like mobile phones no longer retaining charge and typically the battery becoming hotter when charging. In contrast, energetic failure is not normal and involves a rapid release of heat from a cell which can lead to fires. Thermal runaway is where the battery experiences a self-sustaining increase in temperature due to a chain reaction within the battery. It can result in extremely high temperatures, violent cell venting, smoke and fire.

Marie explained that the common causes of failure include:

- Thermal abuse, where heat is applied and/or the ambient temperature is elevated;

- Mechanical abuse involving physical damage to the battery, or water ingress through cracking of the enclosure;

- Electrical abuse, including overcharging, excessive discharge rates or short-circuiting;

- Manufacturing defects.

Marie highlighted that the most concerning failures are those which initially seem to have occurred for no apparent reason. These are most likely due to manufacturing defects, problems within electrodes, the separator, or with seals on the cell allowing the electrolyte to leak and cause a short circuit in the battery.

Materials Engineer and Fire Investigator, Jon Emm, rounded off the presentations with his discussion on Domestic Roof Fires. Jon explained that these incidents are relatively common, can often lead to large claims and can spread to other properties affecting more than one claimant. He advised that the common causes usually occur from human activity (e.g. damaging cables when undergoing work or moving items around), electrical failures, hot work failures and problems with flues/chimneys (e.g. a blockage or foreign material in the flue or hot gases leaking out of it).

Jon explained how a fire investigator would approach an incident of this type by considering typical causes and beginning to assess concerns before arriving on site. The investigator may be able to gather information from an external viewpoint before entering the building or, where a building may be unsafe to enter or difficult to access, our investigators can make use of drones to capture aerial images. Our investigators will often speak to witnesses to gather as much information as possible and Jon explained that asking the right questions is a key part of Hawkins’ investigations. In addition, exploring all potential causes, obtaining clues for what to look for, and assessing the history of problems and relevant activities are all things to consider when conducting an investigation to ensure the correct conclusion is reached.

Hawkins investigates incidents in over 60 different disciplines and regularly gives presentations on these subjects to our clients and insurance-related organisations. If you would like any of our investigators to present to your organisation or to investigate a case, please get in touch.